Our Platform

The PrintBio technology platform is unique because it creates living tissue implants with exceptional performance and was purpose-built to meet the FDA’s requirements for therapeutic manufacturing. The platform includes novel and proprietary 3D-bioprinter (GMPrint™), bio-ink (ColVivo™), specialized cell culture system and implantable protective shell (Overshell Technology).

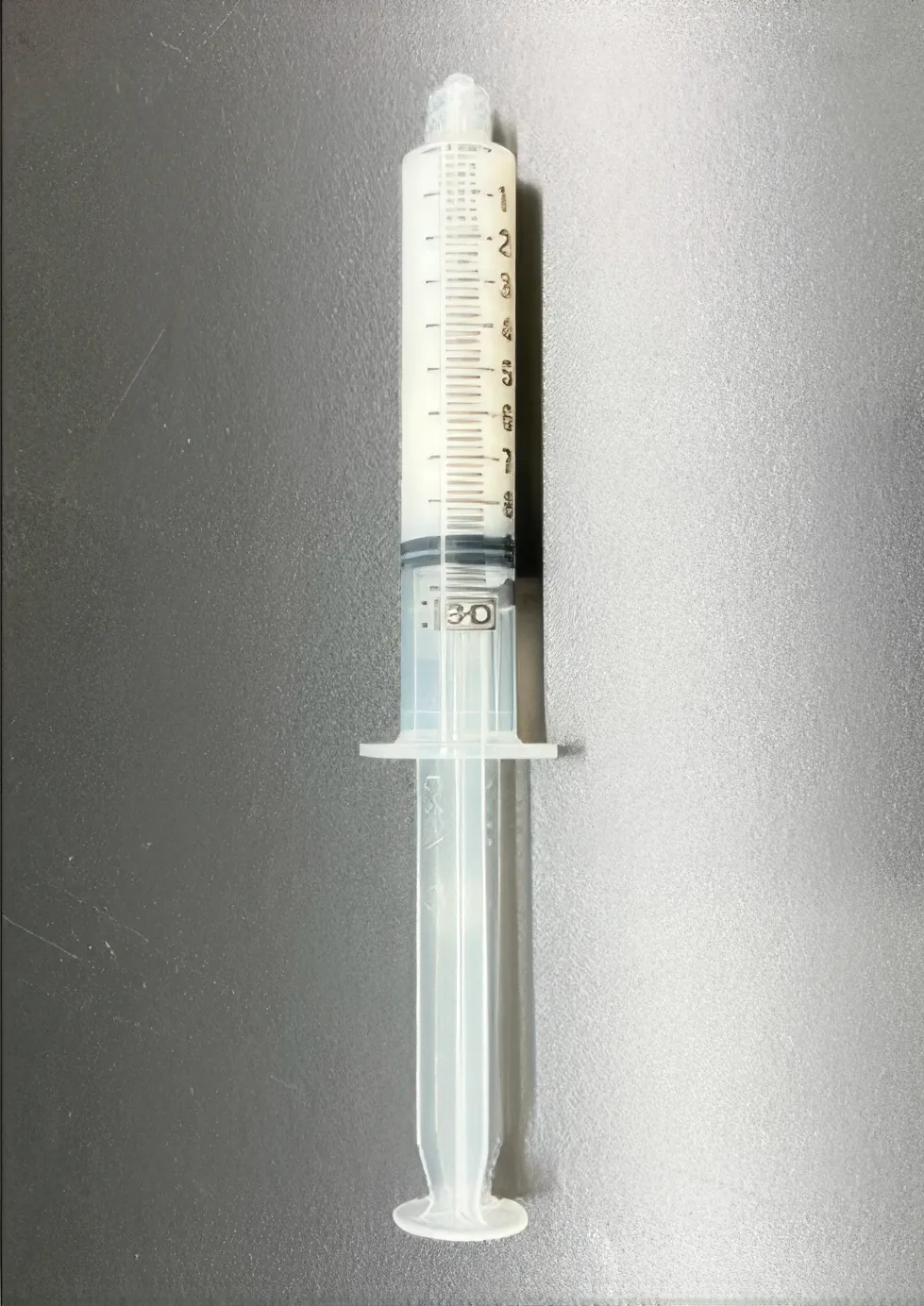

Therapeutic-grade bio-ink

ColVivo™ is a therapeutic-grade bio-ink platform, developed and manufactured by PrintBio, specifically for therapeutic applications of 3D-bioprinting. The bio-ink was created to meet cGMP processing requirements for therapeutic use, while preserving key biological and rheological properties essential for 3D-bioprinting. As a bio-ink, ColVivo™ carries living cells within it and is shaped into living implants in conjunction with the GMPrint™ 3D-bioprinter.

PrintBio has deep expertise in cell extraction, expansion, and storage processes, in addition to its capabilities in 3D-bioprinters and materials. PrintBio has developed its own proprietary processes to ensure that, before incorporation into the bio-ink, the cells are rapidly expanded in sufficient quantity while maintaining appropriate functionality, throughout the printing process as well as when the tissues are implanted.

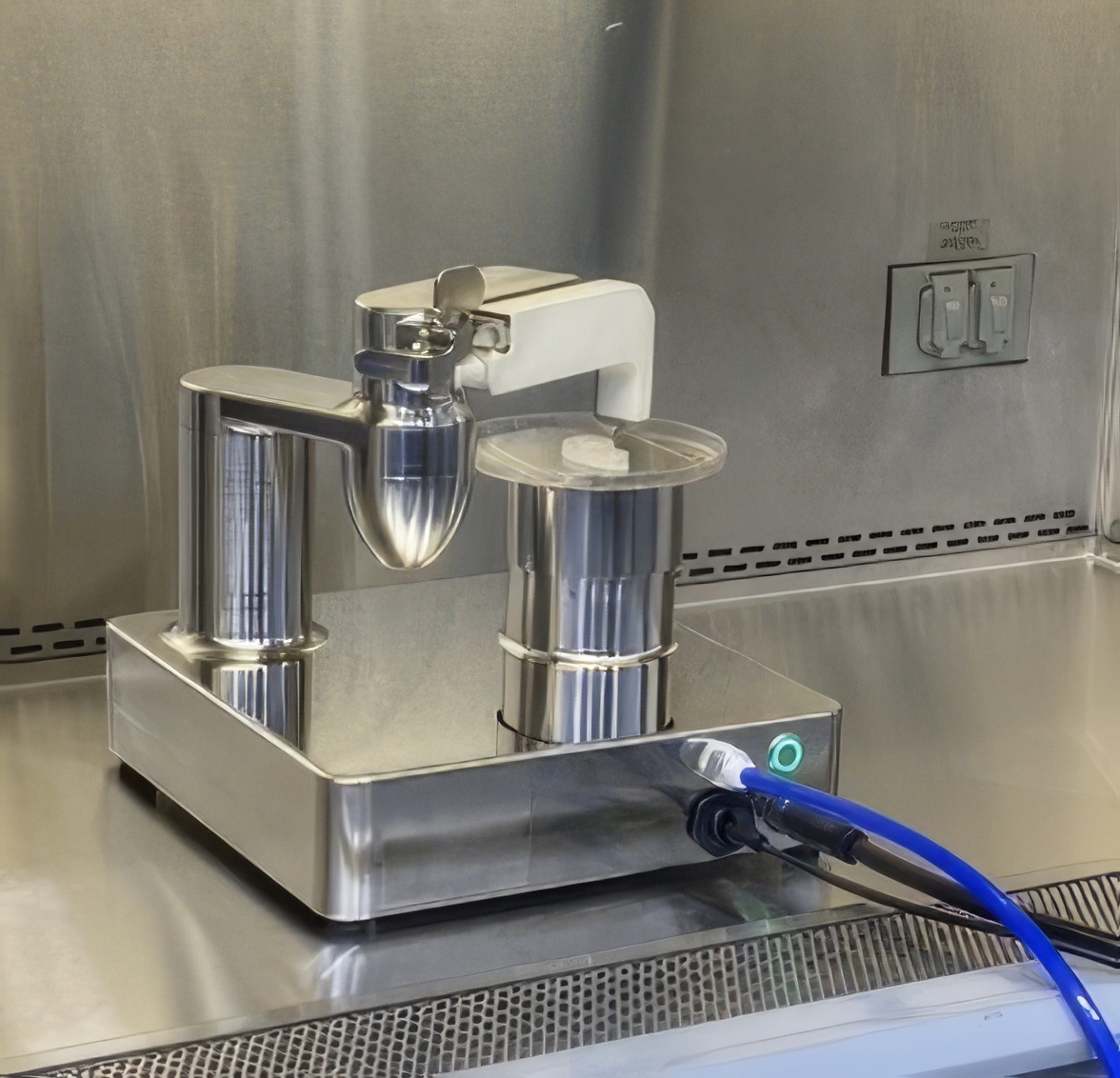

GMP-Compatible 3D-Bioprinter

GMPrint™ technology is a purpose-built therapeutic-grade 3D-bioprinter, designed and manufactured by PrintBio. Research-grade systems do not meet key requirements set by the FDA for manufacture of therapeutics, broadly referred to as current Good Manufacturing Practice (cGMP). GMPrint™ comprises several proprietary, and patented, features enabling aseptic workflow combined with exceptional quality and speed. The GMPrint™ technology also includes an AI-based print-path planning algorithm to optimize tool paths for complex materials and geometries.

- Single-use disposals kit

- Proprietary Aseptic workflow design

- Proprietary motion system for precise ultra-high acceleration

- Ultra-high throughput (>10 million cells per minute)

- CFR21 part 11 compliant firmware and software

- Proprietary path-planning algorithm leveraging A.I. to optimize for Bio-Ink material properties

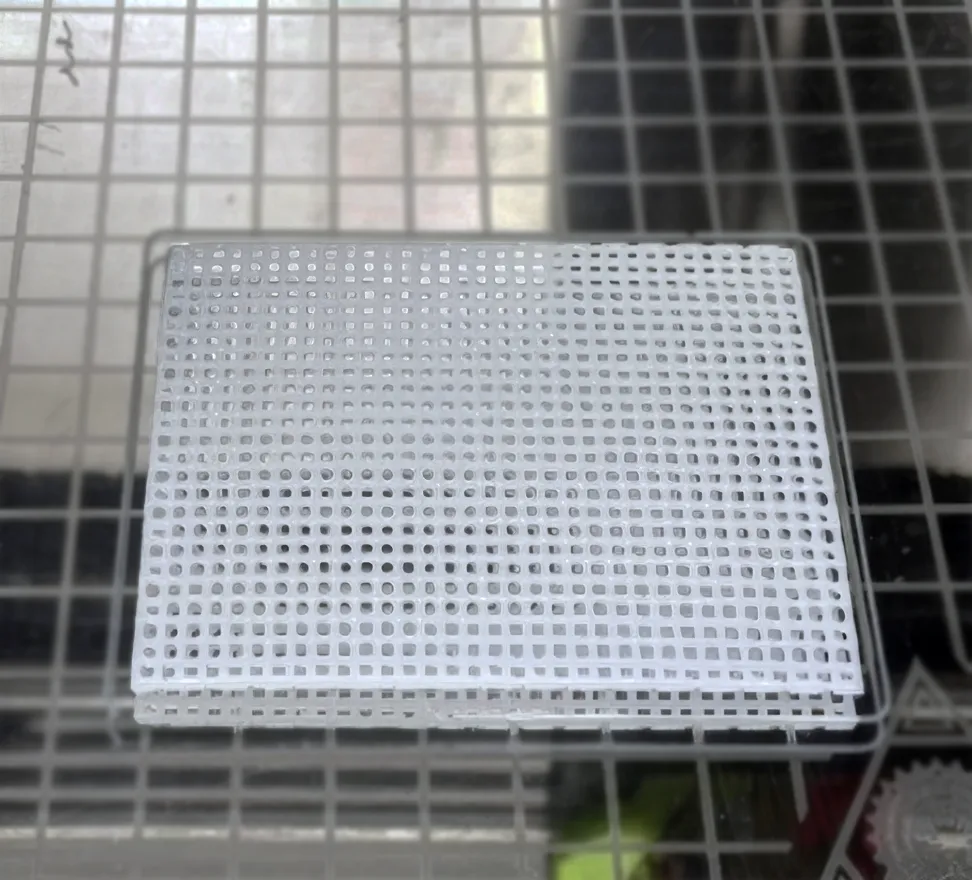

The Overshell is a proprietary technology PrintBio has developed to provide a means for adding non-permanent structural support to biological implants where desirable (e.g. surgical handling and early mechanical function) while supporting their biological function and the patient’s tissue regeneration processes. This is made possible through its unique design and 3D printed and thermoformed structure that matches bioprinted tissue surface geometries and acts as an exoskeleton for a biological tissue implant. The Overshell is fabricated from a bioresorbable polymer with a long history of safe use in implantable devices. Our experience and materials developed for the Overshell are the basis of 3DMatrix™, our bioresorbable monofilament mesh product for surgical reconstruction.

Aureo™ Process

PrintBio’s Proprietary Manufacturing Process for Aureo™ for Congenital Microtia Patients

- A small biopsy is performed on the patient’s microtia ear remnant and sent to PrintBio’s GMP manufacturing facility.

- The patient’s cartilage cells are isolated from the biopsy, expanded in cell culture, and then “printed” into the shape of the patient’s normal ear using PrintBio’s proprietary innovative printing technology

- The components to accomplish this comprise PrintBio’s proprietary platform, including ColVivo™, its therapeutic-grade collagen bio-ink and GMPrint™, its proprietary, clinical grade 3D-bioprinter

- The newly bioprinted “ear” is then sent to the clinic and implanted into the patient in an outpatient procedure

Actual image of 3D-printed Aureo™ “living” ear for reconstruction in Microtia patients